The Sintering Process of Iron Ore Fines. satyendra; March 9, 2013; 4 Comments ; flux sinter, Iron ore fines, self fluxing sinter, sinter, sinter machines, Stright line machine. circular machine, super fluxed sinter,; The Sintering Process of Iron Ore Fines. Sintering plants are normally associated with the production of hot metal in blast furnaces in integrated steel pants.

The Sinter Plant Department at Tata Steel on

According to Tata Steel, the technology removes numerous energyintensive steps – including having to preprocess the ore and coal in separate coke, sinter or pellet factories. Test campaigns were conducted using steel scrap and biomass and created carbon reductions of more than 50%.

Download Citation | Sinter Plant 4 at Tata Steel, Jamshedpur: Benchmarking productivity and energy efficiency | Some of the significant features of Tata Steel''s Sinter Plant 4 (SP4) at its

Sinter Making Long Product Mills Flat Product Mills Billet Caster Slab Caster Ore Mining Coal Mining Captive Purchased Ore, Flux, Coal Casting Rolling. Slide No. 4 Energy Mix of Tata Steel Jamshedpur FY''18 Pur. Power 2638 GWh ( MGcal) Pur. Pellet 105457 T ( MGcal) Pur. Oxygen 1458x106 m3 ( MGcal) Pur Nitrogen 919 x 10 6m3 ( MGcal) PetroFuel 5435 KL (

Involves mining, crushing, washing, screening and shipping the sinter fines and pellet fines to Tata Steel''s European steelmaking facilities. Taconite project. Conducting a Feasibility Study of the LabMag and KeMag iron ore deposits, which form a part of the 150 kmlong Millennium Iron Range in northern Canada. An integrated value chain . Tata Steel is one of the few fullyintegrated global

Material is put on a sinter machine in two layers. The bottom layer may vary in thickness from 30 to 75 millimetres ( to in). A 12 to 20 mm sinter fraction is used, also referred to as the hearth layer. The second, covering layer consists of mixed materials, making for a

Solid Wastes Recycling Through Sinter Status at Tata Steel U. S. YADAV, B. K. DAS, ASHOK KUMAR and H. S. SANDHU Tata Steel, Jamshedpur831001 ABSTRACT Integrated steel plants generate several byproducts rich in iron, flux and fuel values, categorised as waste. These byproducts contain, besides mineral values, hazardous constituents causing damages to the environment. The

Uitstoot Tata Steel veel hoger dan toegestaan, onderzoek naar alle fabrieken De koelers van de sinterfabriek van Tata Steel stoten anderhalf tot twee keer zoveel stof uit als volgens de vergunning

Provincie trekt boetekleed aan: handhaving op uitstoot sinterkoelers Tata Steel ondermaats. 15 januari 2020, uur · Door Redactie

Tata Nirman, quality product from Tata Steel IBMD is an environment friendly material available in 06mm size fraction. It finds its usage in different applications ranging from fly ash bricks, paver blocks, AAC block, concretes to road construction and sinter making. An ideal product, Tata Nirman is a substitute of sand, lime and cement raw materials for manufacturing Fly Ash Bricks. It is

The 2,000acre site at Scunthorpe is an integrated site – this means the raw materials for steel manufacture are transported to the site, where they are ultimately converted to steel. The starting point – refining the raw materials. Highquality coke is made at our Coke Ovens – coal, sourced from all over the world, is charged into the top of each oven and heated at around 1,100°C for

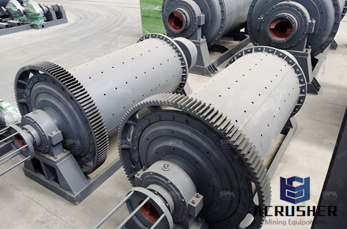

Sinter plants convert fine iron ore into sinter, an agglomerated product suitable for feeding into blast furnaces. About Tata Steel in Europe The European operations of Tata Steel comprise Europe''s second largest steel producer. With the main steelmaking operations in the UK and Netherlands, they supply steel and related services to the construction, automotive, packaging, lifting excavating

# Tata Steel # sinter plant # Jamshedpur News # टाटा स्टील के सिंटर प्लांट में उपचुनाव # टाटा स्टील # सिंटर प्लांट # जमशेदपुर समाचार # News # National News # Jharkhand news; जमशेदपुर में कोरोना वायरस से जुडी

The sinter plant is part of the initial steps carried out to make steel, making sinter by heating up iron ore, lime and sand. The sinter then goes into the blast furnace to make iron. The sinter

2013 | Tata Steel in Europe. Tata Steel is to complete a major environmental improvement project at its IJmuiden steel plant in the Netherlands more than a year ead of schedule. The pace of progress in installing the new bag filter facility in IJmuiden''s sinter plant* will enable it to be fully operational by the end of this year, more than

Tata Steel initiative identifies and accelerates improvements in projects related to operational and functional excellence across the business value chain

Tata Steel er en del af Tata koncernen, der er Europas næststørste stålproducent med en årlig omsætning på over GBP 12 milliarder og en produktion af råstål på ca. 20 millioner tons. Tata Steel har primært sin vigtigste stålproduktion i Storbritannien og Holland og leverer stålløsninger og tilhørende løsninger til . Læs mere

Rakesh Ambastha is Chief:Sinter Plant at Tata Steel Ltd. See Rakesh Ambastha''s compensation, career history, education, memberships.

sinter plant tata steel. Compact AUMUND conveyors for TATA Steel sintering plant in . Apr 17 2015 · The conveying capacity has been designed for 250 t/h of hot sinter at a material temperature of 5001 000°C. Compact AUMUND conveyors for TATA Steel sintering plant in . Get Price; Energy Efficiency Solutions by Primetals Technologies . Customer TATA Steel Port Talbot. Typ of plant Gas recovery

Bedding, Blending and Sinter Plant known as BBSP2 Plant started its ourney in the year 1988, when Tata Steel embarked upon PhaseII of its Modernisation Programme to augment sinter production to 2

A global provider of process solutions, technologies and services for the mining and metallurgical industries, Finlandbased Outokumpu Technology (Outotec) has announced that it has been awarded a contract by Tata Steel for the design and basic engineering of an iron ore sinter plant, the supply of proprietary equipment and provision of supervisory services for Tata Steel''s new Kalinganagar

Sinter Making Full Time Engineering Degree / Diploma in any discipline from a recognized institute or Ex OT. At least 5 years of experience, in Tata Steel for Engineering Graduates/ equivalent and at least 7 years of experience in Tata Steel for others. 9. Steel Making (Including Refractories LCP) Full Time Engineering Degree / Diploma in any discipline from a recognized institute or Ex OT

Tata Steel Ltd (Sinter Plant Division) near Bistupur, Jamshedpur listed under . Call for more information | Justdial. »More detailed. Tata Steel Sinter Plant – Mecon Limited. SINTER PLANTS AT TATA STEEL 54TH Operating Committee Meeting Ranchi 2122 July, 2011 »More detailed. companies construct ferro manganese plant – Crusher South Africa. MOIL Limited To explore all

WhatsApp)

WhatsApp)