Production Performance Analysis on Wet Marble Grinding Mill. Structure of wet type marble grinding mill is more complex compared with that of other marble grinding ...

· Ball mill is the key crushing equipment which used to recrush materials after they receive the ... reliable performance. Dry ball mill and wet latticetype ball mill can .

how to optimize ball mill performance. how to optimize ball mill performance, Meet Your Material . how to optimize ball mill paul o abbe equipment company is a ...

ball and tube mill perfomance improvement ... difference between raymond mill and ball mill. Pre: ball mill production performance Next: dlamant gringing mills moulins.

CEMENT GRINDING OPTIMISATION ... The electrical energy consumed in cement production ... The basis for modeling the twocompartment ball mill is the perfect .

Design and Optimization of Ball Mill for Clinker Grinding in Cement ... production. The performance of ball mill depends on number, ... optimal ball mill performance.

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

ball mill production performance. Effect of gallium doping and ball milling process Resech Online process, milling, ball, doping, zno, type, gallium, n, ...

In cement production line, rotary kiln, ball mill is the indispensable equipment. rotary kiln and ball mill production by Henan Zhengzhou Mining Machinery Co., Ltd ...

Correlations for the Grindability of the Ball Mill As a Measure of Its Performance ... of the ball mill. 2. Literature Ball mills are ... production process at two ...

The inlet of the mill production efficiency here Ball mill in normal operation, the device output to a large extent by a single material feed rate of the direct ...

How to improve ball mill production?ed in mineral processing, building materials and chemical industry as a general grinding mill equipment. Chat Online

Ball Mill Introduction: Mobile cone crusher is mainly used in the field of crushing operations in aggregates production operations, according to the use of different ...

· Improve mill performance in sand production line The process of hardening or setting is actually a chemical reaction called hydration. When water is added to the ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

Ball Mills are primarily used for fine grinding. Ball Mill is key equipment which repulverises the material after it is crushed. Ball Mill is widely used in powder ...

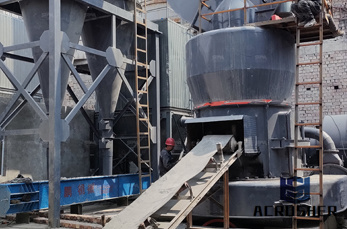

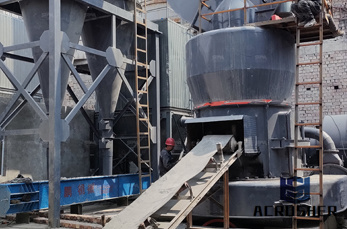

Grinding Ball Mill Production Site Cement Grinding Mill Production Site Professional clinker grinding plant in cement production, bringing more economic benefits for ...

The ball load and pulp load have a significant influence on the ball mill product size and production capacity. To improve the circuit performance at industrial scale ...

Ball mill is the material is the key equipment to crushing the broken material. Ball mill is widely used in cement, silicate products, new building materials ...

The Performance and Application Range of Ball Mill and Rod Mill News Date: 14:53:14. Ball mill and rod mill are widely used in ore dressing plant, and grid ...

OPTIMIZING BALL MILL LINERS FOR PRODUCTION AND ECONOMY. on ResearchGate, the professional network for scientists.

China Ball Mill manufacturers Select 2017 high quality Ball Mill products in best price from certified Chinese Milling manufacturers, Plastic Machinery factory ...

high performance ball mill manufacturer/supplier, China high performance ball mill manufacturer factory list, find qualified Chinese high performance ball mill ...

Ball Mill. INPUT SIZE : ≤25mm OUTPUT SIZE : PRODUCTION CAPACITY : Up to 35TPH capacity, depends on the size of fineness PROCESSED MATERIALS : .

WhatsApp)

WhatsApp)